AQUA MISR Filter Cages | |

|

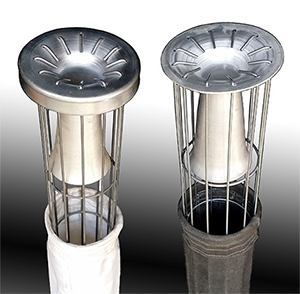

Filter Cage is one of the important components in Pulse Jet Bag House, it plays important role in filter operation, and if any problem

occurs in the cage it will affect the filter operation.

The design of filter cage is vary depending on the design of tube sheet, bags, and how to fix the bags in the tube sheet.

We can summaries the role of the cage in the following points:

- The cage used to fix the bags in the tube sheet

- Support the bags and maintain its shape to be round

- Prevent the bags from collapsing under pressure during filter operation

- Lead the pulse jet inside the bag to ensure cleaning the total length of the bag

|

|

|

Our standard design for cages uses the cone-shaped Venturi mounted over the top of a tubular filter cages to

direct the compressed air from the pulse-jet valves by creating a negative pressure for pulling additional air down into the filter elements during pulsing which clean the bags

efficiently |

|

We provide the market with rotary airlocks valves for many applications specially for baghouses, our production range:

Diameter: 200 mm - 1000 mm

Body Material: Carbon steel or stainless steel |

|

|

AQUA MISR uses only high-quality material (most commonly used materials are galvanized, stainless steel and carbon steel) to ensure a reliable and precise product, suitable even for the most modern air filtration and cleaning equipment.

Our cages production line can create cages with round and starshaped section they are produced only under customer's specifications.

|

|

We provide the market with rotary airlocks valves for many applications specially for baghouses, our production range:

Diameters can vary from 115mm to 195mm (maximum 24 wires) with length up to 7mt, and they can be realized in one part or more than one part. |

|